Mold design is a model of the shape of the part to be cast, prepared from wood, metal or a suitable material. These designed molds can be produced as one piece, two or more pieces, makeshift pieces, and records. In the mold design, by paying attention to the processing allowance, shrinkage allowance, the conical structure of the mold, the warping margin, it should be possible to produce in the desired size and model without damaging the mold or the product.

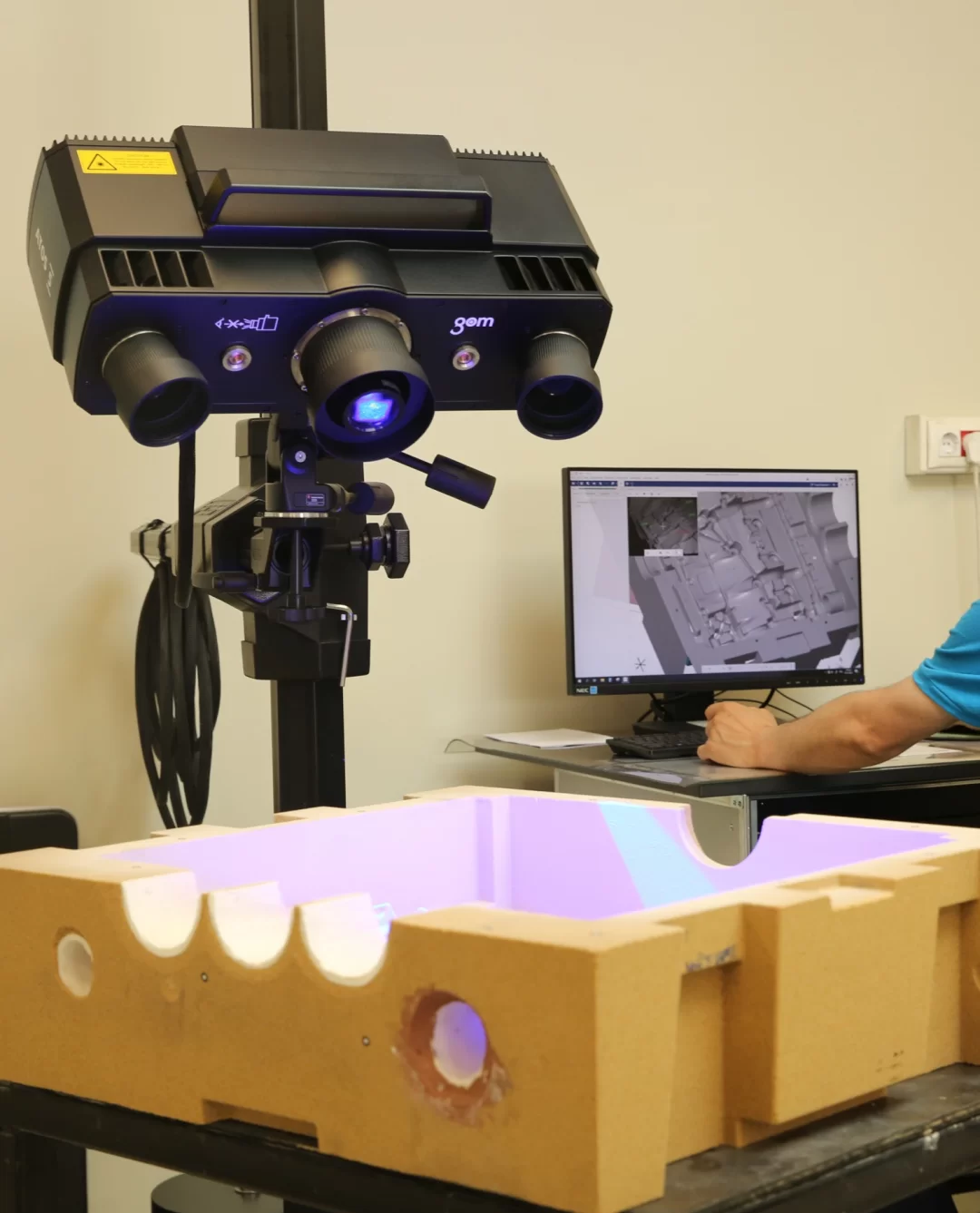

Mold designs are created by expert teams using the SIEMENS Nx CAD program over the 3D data of the parts requested to be cast. Casting simulation is done by using Solid Cast simulation program and mold production is started after obtaining optimized results. With the SIEMENS CAM program, mold processing and assembly are done with CNC machines. Every stage of mold making is controlled by the joint work of mold, casting, machining experienced quality control and engineer teams. Defect-free production of the controlled products is ensured.